4 Layer High Frequency PCB Built On 6.6mil and 20mil RO4350B with Blind Via for Radar Sensor

(Printed circuit boards are custom-made products; the pictures and parameters shown are for reference only.)

Introduction

Hi Everyone,

Multilayer Rogers PCBs are constructed using multiple cores combined, distinguishing them from conventional FR-4 multilayer PCBs. The RO4350B family includes eight core thickness options, ranging from 4mil (0.101mm) to 60mil (1.524mm).

.jpg)

Thickness (mil) |

Thickness (mm) |

4mil |

0.101mm |

6.6mil |

0.168mm |

10mil |

0.254mm |

13.3mil |

0.338mm |

16.6mil |

0.422mm |

20mil |

0.508mm |

30mil |

0.762mm |

60mil |

1.524mm |

The stacking of four layers can be achieved in various configurations.

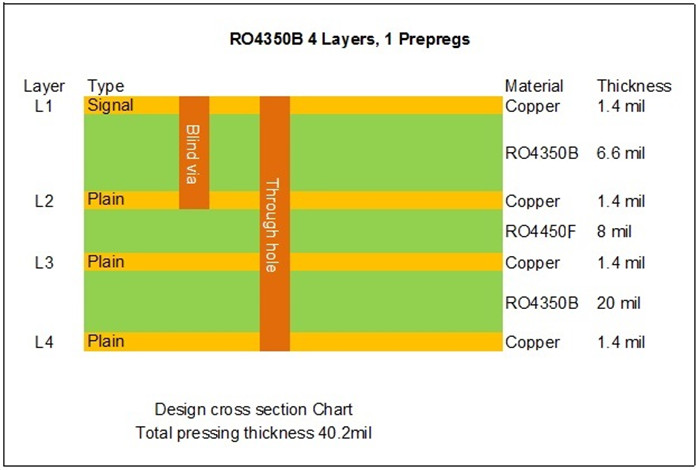

Today, we introduce a Rogers 4-layer PCB built on 6.6mil and 20mil RO4350B for radar sensor applications.

Let’s see first one and stack-up is shown first.

This RF board features a thickness of 1.0mm with a minimum track width of 4mil and a gap of 5mil. It is a high-frequency multilayer PCB using RO4450F as the dielectric prepreg. The board has white silkscreen over green solder mask, with immersion gold plating on pads. Each panel is supplied as a single unit, fabricated to IPC 6012 Class 2 standards using provided Gerber data. Ten boards are packed for shipment.

Stack-Up Details:

Layer 1 to Layer 2: First core of 6.6mil

Layer 3 to Layer 4: Second core of 20mil

Combined with two sheets of RO4450F (1 RO4450F = 4mil

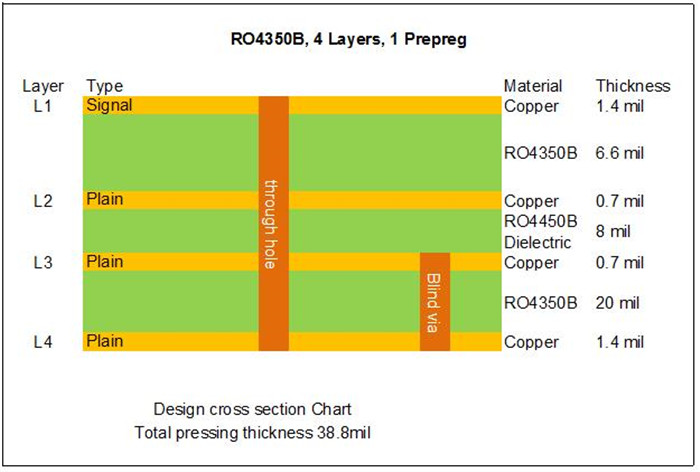

The second one is very similar to previous one, the stack-up explains all.

Features and Benefits:

1.Low Dielectric Constant: Ensures excellent high-frequency performance and minimal signal delay.

2.Surface Planarity: Immersion gold provides superior surface flatness, crucial for BGA packages and CSP mounted components, reducing assembly failures.

3.Comprehensive Testing: All PCBs undergo 100% electrical testing, AOI inspection, thermal stress testing, reliability testing, insulation resistance testing, and ionic contamination testing.

4.Rapid Production: Efficient processes facilitate a quick turnaround, from prototypes to standard production runs.

5.Compliance: UL recognized and adheres to RoHS Directive standards.

Applications:

TV Antenna

Transmitter Combiner

Sound Control Switch Induction

Tower-Mounted Amplifier

RF Module

Power Splitter

Low Noise Block

4G Antenna

Why Choose Us?

1.Focus on Core Competencies: Our collaboration allows you to concentrate on essential areas like research and development, while we handle the technical aspects with our expert services.

2.Cutting-Edge Technology: Partnering with Bicheng PCB provides access to advanced manufacturing capabilities across our three factory bases, totaling over 26,000 square meters.

3.Cost Efficiency: We strive to reduce production costs through improved technology and efficient training, ensuring profitability without compromising quality.

4.Quality Assurance: Our engineering designs proactively prevent quality issues during pre-production. With a customer complaint rate below 1%, we prioritize your satisfaction.

5.Timely Delivery: We recognize the need for quick market responsiveness, offering fast and flexible production processes for prototypes and standard orders.

6.Experienced Team: Bicheng is a reliable partner, committed to professionalism and integrity. If you're contemplating a supplier change, Bicheng is your ideal choice.